Hardware

Configure the perfect device for your application.

Step 1: Start with your communication box

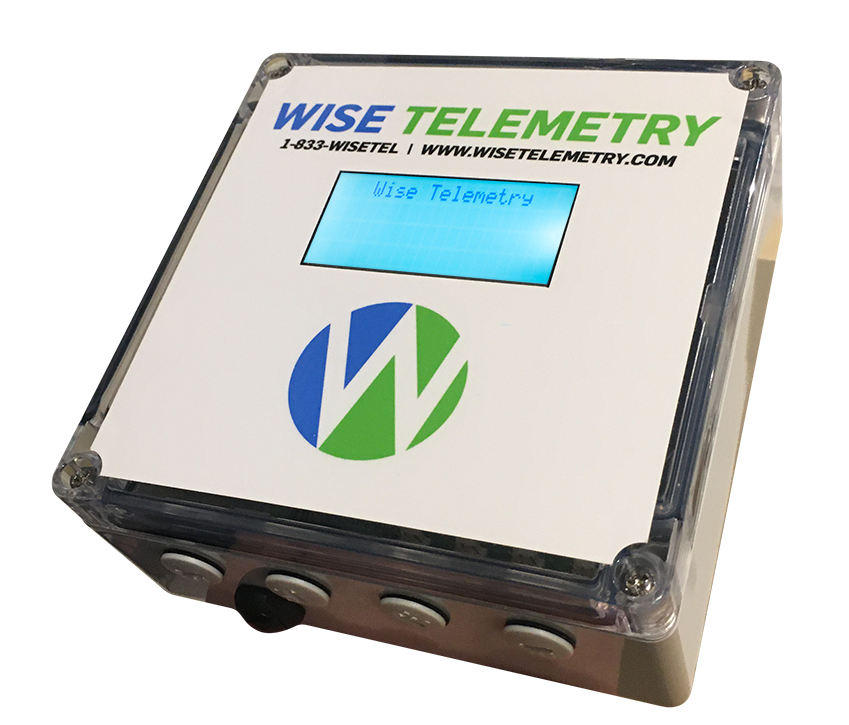

The Elite 2.0

At the heart of our telemetry systems is the Elite 2.0 communication box. The communication box takes readings from its sensor ports and transmits these readings via cellular communication to the Wise Telemetry dashboard.

Key features include:

- 24 readings per day

- 4 sensor ports standard

- 4G LTE-M coverage from the leading domestic and international networks

- GPS capability

- Powered by rechargeable battery and solar or wall power

- Optional display screen (shown here)

- Supports 4-20mA, 0-5V, UART, I2C, SPI, and contact switch sensors

Step 2: Select the sensors for your communication box

Differential Pressure Sensor

Differential pressure is a simple and reliable way to monitor the liquid level in cryogenic gas tanks. These sensors work by measuring the pressure at the top of the tank and subtracting it from the pressure at the bottom. The resulting value is the pressure from the liquid within the tank which can be converted to a fill level.

Wise Telemetry’s differential pressure sensors feature the following specifications:

- Oxygen cleaning standard

- 0-600 in. H2O range

- 4-20mA output

- +/- 0.5% accuracy

- 1/4″-NPT fittings

Single Pressure Sensor

Monitoring the head pressure within a cryogenic gas tank can provide valuable information about how that tank is performing. Additionally, cylinder manifolds and bundle packs can be monitored with these robust sensors.

Wise Telemetry’s single pressure sensors feature the following specifications:

- Oxygen cleaning standard

- 0-500psi or 0-3000psi range

- 4-20mA output

- +/- 1.0% accuracy

- 1/4″-NPT fittings

Capacitance Probe

For liquid cylinders and dewars that don’t have dedicated differential pressure taps, capacitance probes are an accurate and effective solution. These probes are inserted into the top of the tank and measure the liquid level by sensing the height of the liquid in relation to the height probe.

Wise Telemetry’s capacitance probes feature the following specifications:

- 0-100% calibrated range

- 4-20mA or 0-5V output

- +/- 0.1% accuracy

- Custom cut to tank length

Example Configuration – Bulk Gas Monitor

Wise Telemetry’s systems are extremely customizable. Here is an example of our most common configuration for monitoring bulk cryogenic gas tanks. This configuration includes:

- Elite 2.0 communication box

- Display screen

- Solar power recharging system with mounting bracket

- One differential pressure sensor

Want to use a different type of sensor?

No problem. The Elite 2.0 can be used with any standard 4-20mA or 0-5V sensor providing a wide variety of possibilities for measuring temperature, proximity, light, pH, flow, and humidity. Contact us below, and we will find the right sensor for you.

Which gases can be used with this system?

The Elite series can be used with nitrogen, oxygen, argon, carbon dioxide, and helium. Additional gases may be available upon request.

Can this system be retrofitted onto my existing tanks?

Yes. The Elite series can be retrofitted onto most existing tanks.

Does this system require multiple pieces of hardware?

No. The Elite series is only one piece of hardware that both senses the liquid level and communicates these readings from the tank to the Wise Telemetry dashboard.

Can this system be used outdoors?

Yes.

How does the device communicate data?

Our devices can communicate via 4G LTE-M connections.

How do I access my data?

Data from Wise Telemetry devices can be accessed online via our secure web portal. Alternatively, Wise Telemetry software can interact with APIs for ERP, asset tracking, and route planning systems.